Overview

Waterproof breathable fabrics are designed to keep you dry while allowing moisture to escape during physical activity. These fabrics typically come in 2-3 layers and operate on a fundamental principle: their pores are too small for water to penetrate but large enough for body vapor to pass through. To achieve these properties, manufacturers employ either laminate technology or coatings.

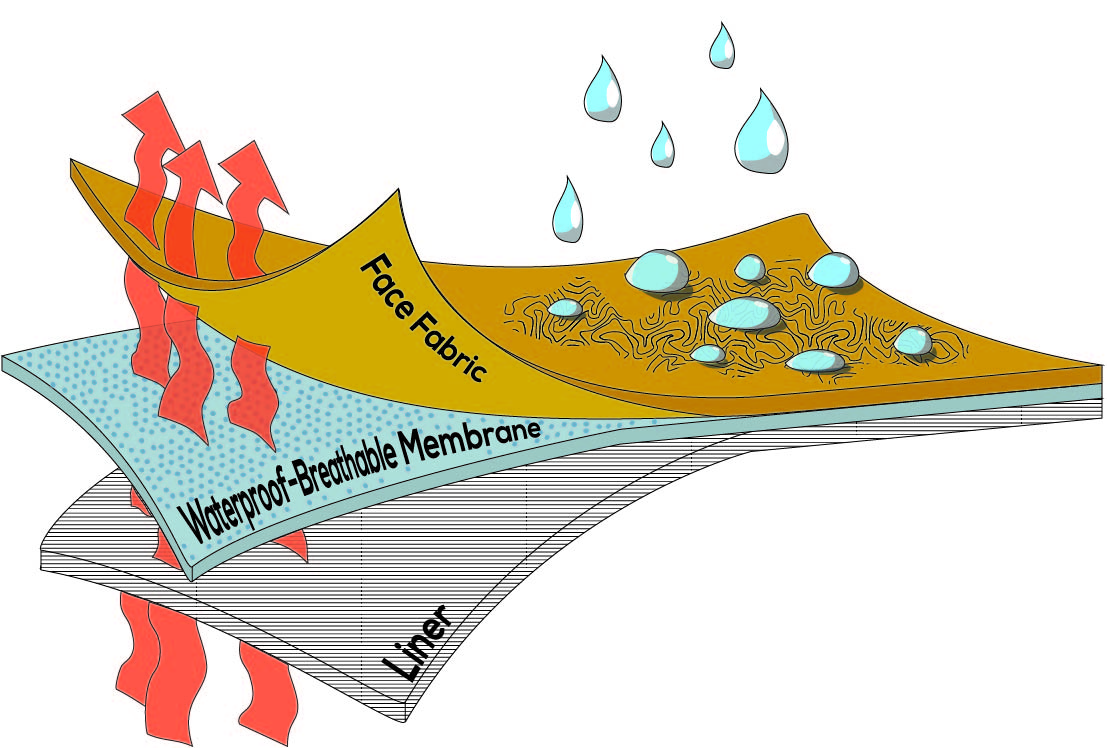

Fabric Components

Waterproof breathable materials generally consist of an outer layer called the face fabric (typically nylon or polyester), a laminated membrane or coating (constructed from ePTFE or PU), and occasionally a backer lining for added durability. The face fabric provides color and protection, although it is not inherently waterproof. The key waterproof layer is the membrane, which has minuscule pores that repel liquid water while permitting water vapor to escape. In 3-layer fabrics, an additional layer is bonded for comfort. While most waterproof breathable fabrics excel in waterproofing, they vary in breathability and other aspects.

Laminates

At the core of laminate fabrics lies the waterproof membrane, which is fused to the fabric using heat and pressure. These membranes are typically composed of expanded polytetrafluoroethylene (ePTFE) or polyurethane (PU) films.

Expanded Polytetrafluoroethylene (ePTFE)

ePTFE membranes feature intricate web-like structures only about 10 microns thick, containing billions of pores. These pores are approximately 20,000 times smaller than raindrops, rendering ePTFE hydrophobic (water-repellent). ePTFE is characterized by its low surface energy, tightly binding its atoms together. Water, with its high surface energy, forms round droplets on ePTFE's surface, preventing penetration. However, ePTFE can be compromised by contaminants like dirt, body oils, sweat, or pesticides, altering its surface energy and potentially leading to leakage. Making ePTFE oleophobic (resistant to oils) helps prevent contamination.

Gore-Tex®

Gore-Tex® pioneered ePTFE-based waterproof breathables, using a lightweight membrane with microscopic pores that block liquid water while allowing water vapor to escape. Today, Gore-Tex® laminates their ePTFE membrane directly to a high-performance face fabric.

eVent™

eVent™ also employs ePTFE but infuses it with polyacrylate to enhance breathability, though this may reduce durability compared to Gore-Tex®. Unlike Gore-Tex®, which applies a separate layer onto the membrane, eVent™ introduces protective ingredients directly into the membrane, creating a unique waterproof membrane with tiny pores that allow breathability while repelling water. However, in cold, dry conditions, excessive breathability can lead to heat loss, necessitating additional insulation.

Polyurethane Films (PU)

PU laminates combine a lightweight fabric with a thin polyurethane film, resulting in a flexible, breathable, water-resistant fabric. PU films offer good stretch, complete waterproofing, and maximum comfort. They are often lighter and more compact than ePTFE laminates, accommodating stretch in garment designs and proving highly durable, suitable for demanding environments.

Coatings

Coatings involve applying a layer of polyurethane resin directly onto the fabric, using two mechanisms: microporous and monolithic.

Microporous Coatings

Microporous coatings have small pores that allow vapor to pass through but are smaller than raindrops, ensuring breathability while repelling water. These coatings have pores ranging from 0.1 to 1.0 micrometers, smaller than raindrops but larger than vapor.

Monolithic Coatings

Monolithic coatings are solid, nonporous layers that protect against wind and resist clogging from dirt, detergent, sweat, or dirty water. These coatings pull perspiration off the skin, absorb vapor, and disperse it for evaporation. Coated fabrics and laminates have similar durability, but coatings tend to wear off gradually, while delamination in laminates occurs more rapidly.

Measurements

Waterproof, water resistance, wind resistance, and breathability are tested in laboratory conditions, and products receive ratings for each. Waterproofing is measured in millimeters (mm) of water pressure that the fabric can withstand for 24 hours, with 20,000 mm/24hr marking complete waterproofness. Breathability measurements can vary, but one common metric is the grams of water that can pass through a square meter of fabric over 24 hours (g/m²/24hr). When comparing measurements, it's essential to ensure they use the same scale.

Comments